TMUK’s 25 Objects – 5: Suction Cups

To ensure new car components can be handled quickly and safely, suction cups are used to pick them up.

To ensure new car components can be handled quickly and safely, suction cups are used to pick them up.

An on-site crèche keeps member’s children safe and well.

Green-fingered folk, discover how Toyota Manufacturing UK has built a nature reserve with a little help from the Royal Botanic Gardens at Kew.

Imperfections in the steel used to build TMUK’s cars – some of which are invisible to the naked eye – are taken care of by world-leading microscope tech.

Imagine if as well as making cars, you made the machinery which helps build them. Toyota does just that with its factory’s forklifts.

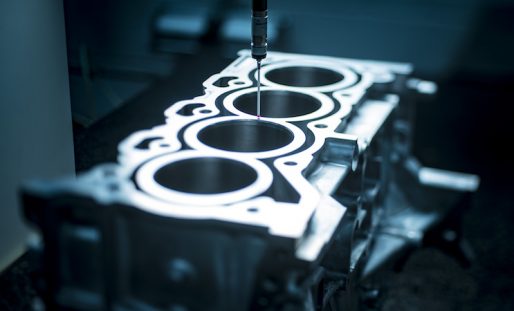

Here’s how the engine block, beating heart of every Toyota, is produced.

Every part has its place and that’s thanks to these humble blue plastic totes.

Self-propelled robots called Automated Guided Vehicles (AGV) ferry parts to members on TMUK’s production line. Oh, and they play songs too!

Mirrors on the production line at Toyota’s Burnaston factory help members keep an eye on production at all times.

Find out why TMUK Paint Shop members’ uniforms are sent for the ultimate cold wash.

No squeak or rattle is left unheard when a freshly built Toyota is driven down TMUK’s punishing Belgian road by a Quality Assurance team member.

Our frozen Toyota C-HR was created to highlight the importance of staying safe during winter with Official Toyota Accessories. Here’s how we did it.

We’ve teamed up with champion drift racer Fredric Aasbø to burn the world’s largest Toyota GT86 logo using nothing but tyre marks.

Fredric Aasbø’s Toyota Express Service 86-X is a 1,000hp one-of-a-kind drift machine. We delve into the details.