TMUK’s 25 Objects – 1: The Spade

It started with a spade. Find out how an area of Derbyshire wasteland came to become a powerhouse of sustainable automotive manufacturing way back in 1992.

It started with a spade. Find out how an area of Derbyshire wasteland came to become a powerhouse of sustainable automotive manufacturing way back in 1992.

In years gone by, the ordering bike provided a vital parts delivery tool. See how things have changed.

No, we’re not having a ‘giraffe’; there really is a crossing at TMUK based on the tall and black-tongued creature. Learn about its vital role in Just-In-Time Production here.

Before each steel panel heads off to the weld shop for assembly, a team member will sign their name on the panel, taking both pride and responsibility for their work.

To ensure new car components can be handled quickly and safely, suction cups are used to pick them up.

An on-site crèche keeps member’s children safe and well.

How much solar power do you think Toyota’s Derbyshire factory generates? Find out here.

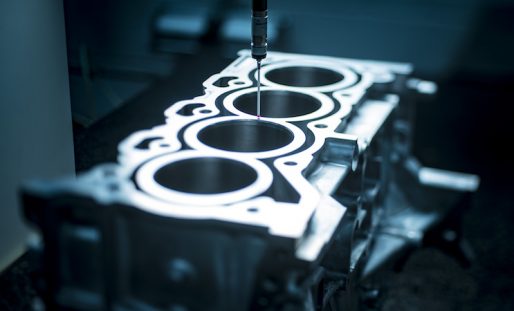

Casting an engine block requires an enormous amount of thermal energy. Enter TMUK’s part-solar-powered furnace.

Green-fingered folk, discover how Toyota Manufacturing UK has built a nature reserve with a little help from the Royal Botanic Gardens at Kew.

Every Auris and Avensis starts its life as a roll of sheet steel. Here’s how the metal is shaped into a vehicle for the road.

Imperfections in the steel used to build TMUK’s cars – some of which are invisible to the naked eye – are taken care of by world-leading microscope tech.

Imagine if as well as making cars, you made the machinery which helps build them. Toyota does just that with its factory’s forklifts.

Here’s how the engine block, beating heart of every Toyota, is produced.

Every part has its place and that’s thanks to these humble blue plastic totes.