Reports of Toyota vehicles in use in conflict zones

Statement and Q&A on reports of Toyota vehicles in use in conflict zones.

In New Tech we describe some of the innovations Toyota is bringing to its range of passenger cars and light commercial vehicles.

Statement and Q&A on reports of Toyota vehicles in use in conflict zones.

Recently, Toyota Motor Corporation unveiled its newest product – a boat! And this got us thinking – what other non-automotive products does Toyota make throughout the world?

We reveal the latest finding in our ongoing search for the oldest British-built Toyota Carina E.

Toyota UK switches on almost 13,000 solar panels to power the car manufacturer’s Deeside factory in North Wales.

We talk to the owner of a used Toyota MR2 to find out what it’s like owning the increasingly rare and sought-after classic.

Want to achieve the best possible fuel economy from your hybrid? Follow these 10 top tips.

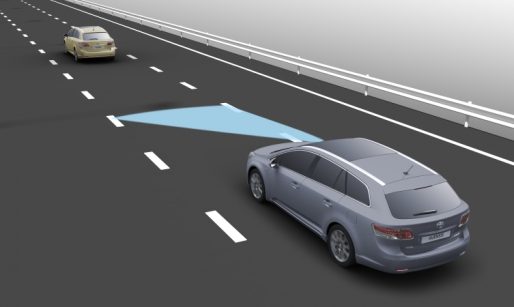

In a multi-part series about safety, we examine Toyota’s monitoring technologies that keep you and your passengers safe on the move

In a multi-part series about safety, we examine convenient technology that Toyota uses to keep you and your passengers safe on the move

In a multi-part series, we examine Toyota’s braking technologies that keep you and your passengers safe on the move

In a multi-part series about safety, we examine Toyota’s stability technologies that keep you and your passengers safe on the move

Bill Yeomans has bought 23 Toyotas from same dealer – is he the UK’s most loyal car buyer?

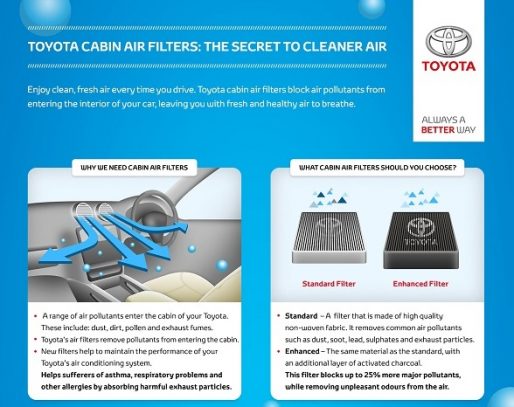

With the focus firmly on improving the quality of the air we breathe, the cabin air filter is the secret to cleaner air in your vehicle.

Toyota factory cements its reputation as a global eco leader by recycling water treatment waste for building material production.

Underpinned by thirteen core processes and philosophies, The Toyota Production System pioneered modern manufacturing as we know it. Here’s what each one is and how each one works.