Why does Toyota compete in motorsport?

Why is Toyota so determined to compete in motorsport? And how do these motorsport activities contribute to the cars we enjoy driving?

Why is Toyota so determined to compete in motorsport? And how do these motorsport activities contribute to the cars we enjoy driving?

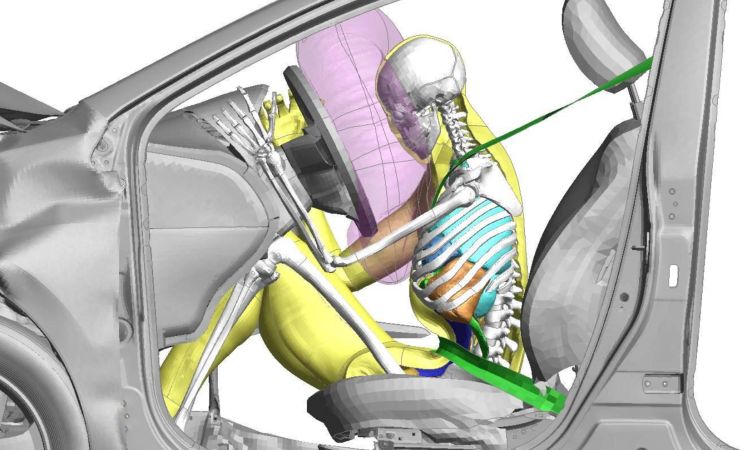

New child models have been added to Toyota’s THUMS software to help mitigate human injuries in the event of vehicle accidents.

If you have a full length canvas roof fitted to your Toyota Aygo, it’s important to take care when cleaning it.

A Konnyaku stone ensures body panels on cars made at our Burnaston factory in Derbyshire are super-smooth.

Take a look at the Toyota Touch 2 with Go multimedia system and how the new 2016 update makes significant improvements on the outgoing version.

The Toyota Production System is focused completely around maximum efficiency and fault-free processes. That’s the idea behind Poka-Yoke.

Recognising and reflecting on mistakes is the key to not repeating them. That’s the principle behind Hansei.

The Andon cable empowers everyone involved in creating a new Toyota – read our explanation here.

Combining automated processes with human intelligence and problem-solving is necessary in industrial-scale manufacturing. That’s why Jidoka is a key part of the Toyota Production System

Round-up of Toyota’s future mobility and automated driving projects as government announces a Modern Transport Bill.

In a multi-part series, we examine Toyota’s safety technologies that keep you and your passengers safe on the move

Next month, Toyota will become the first car manufacturer to use a new biosynthetic rubber product in its engine and drive system hoses.

First service milestone of Toyota’s hydrogen fuel cell saloon proves Mirai maintenance is a breeze.

This is the Toyota uBox, a student-built concept developed in collaboration with Toyota Motor North America for Generation Z drivers.