Toyota Fund for a Better Tomorrow: a year of supporting good causes

We look at how the Toyota Fund for a Better Tomorrow has been supporting grassroots good causes across the UK over the past year.

In New Tech we describe some of the innovations Toyota is bringing to its range of passenger cars and light commercial vehicles.

We look at how the Toyota Fund for a Better Tomorrow has been supporting grassroots good causes across the UK over the past year.

A special Toyota Gazoo Racing project has resurrected a historic 1965 Toyota Sports 800 – possibly Toyota’s oldest surviving racecar.

Within the year, Toyota will have a fleet of 72 hydrogen fuel cell forklifts at its Motomachi Plant, home of the Toyota Mirai. But where will they be refuelled?

Toyota New Global Architecture (TNGA) unlocks exciting design for the new Toyota Auris.

Toyota GB soars into the top 20 of the Sunday Times’ 100 Best Companies to Work For survey.

Concept-i series and Toyota FINE-Comfort Ride make European Debuts at the 2018 Geneva Motor Show.

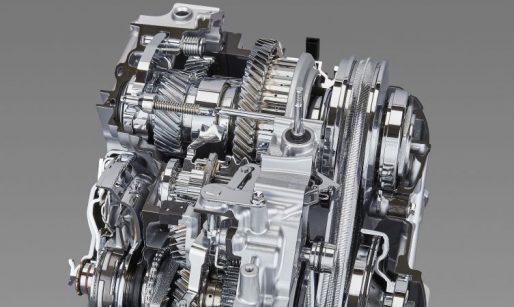

Toyota has developed a suite of new Toyota New Global Architecture engines, transmissions and all-wheel drive systems.

Toyota has made the world’s first neodymium-reduced, heat-resistant electric motor magnet. What breakthroughs enabled its development?

Toyota posts sales of 1.52 million electrified vehicles in 2017, three years ahead of schedule.

Toyota launches a new mobility ecosystem and concept vehicle at the 2018 Consumer Electronics Show.

Toyota Research Institute will introduce its next-generation automated driving research vehicle at the Consumer Electronics Show.

Toyota intends to achieve a 100% reduction in CO2 in Europe by 2035. Electrified powertrains form the heart of this bold strategy.

We speak to the Toyota People who have worked at our Burnaston factory since it opened 25 years ago.

It started with a spade. Find out how an area of Derbyshire wasteland came to become a powerhouse of sustainable automotive manufacturing way back in 1992.