Toyota Yaris Hybrid-R revealed

The Toyota Yaris Hybrid-R concept has been revealed at the Frankfurt Motor Show – get the full details here.

The Toyota Yaris Hybrid-R concept has been revealed at the Frankfurt Motor Show – get the full details here.

The Toyota Aygo is an appealing, four-seater compact car that’s cheap to buy and run without compromising on equipment levels or build quality.

The Toyota Avensis Tourer is a practical and stylish five-door estate that is ideal for the driver who needs a spacious and refined estate car with superb economy and excellent quality.

The Toyota Avensis is a practical and stylish four-door saloon that is ideal for the driver who needs quality and refinement in an affordable larger car while still achieving superb economy.

We take a look back across the pages of the Toyota Land Cruiser history book, from its roots back in 1951 all the way to the present day.

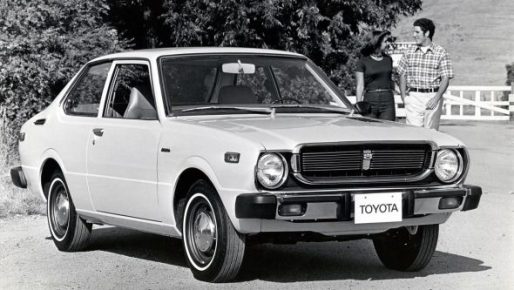

The third-generation Toyota Corolla was developed to meet tightening emissions regulations and in doing so brought many innovations to the entire car industry.

As sales of the Toyota Prius surpass 3 million, we take a closer look at the evolution of Toyota’s pioneering Hybrid Synergy Drive engine technology.

We take a closer look at the second-generation Corolla, which offered greater competence and enhanced performance for the world’s new high speed era.

What could possibly turn the head of an engineer away from his dream Ferrari? Watch this exclusive video about the Hyatt family’s preference for a Prius over Italian exotica.

Meet the first-generation Toyota Corolla, a ‘people’s car’ that stunned the world with its new technology, innovative features and uncommon desirability.

We enjoy unprecedented access to three of Toyota’s legendary GT cars for a once-in-a-lifetime photo and video shoot.

Join us as we take to Twitter with a step-by-step guide to building a new Auris Hybrid at our UK factory. We’ll show you what makes Toyota a World leader in manufacturing.

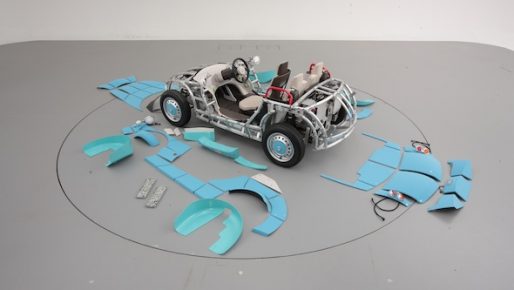

New build-it-yourself Camatte 57s concept unveiled at Tokyo Toy Show.

Our weekly rundown of annual highlights from the Goodwood Festival of Speed continues with Toyota’s tenth appearance in 2011.