The new Toyota Mirai hydrogen fuel cell electric vehicle takes Toyota’s advanced FCEV technology to a higher level, offering dynamic, contemporary styling and a more rewarding and engaging drive.

A comprehensively redesigned fuel cell system, intelligent packaging and improved aerodynamic efficiency help extend the Mirai’s driving range to around 400 miles, with no tailpipe emissions other than pure water.

Toyota began development of a hydrogen fuel cell electric vehicle in 1992 and successfully introduced the first-generation Mirai in 2014. As you can read below, the new Mirai hydrogen FCEV is improved in every aspect.

Mirai hydrogen fuel cell: improved performance

A key priority for the new Mirai has been to improve the driving range compared with the first-generation model, with the aim of exceeding the distances typically achieved by today’s battery electric vehicles. Increased hydrogen fuel capacity, improved efficiency and better aerodynamics all contribute to extending the driving range by 30% to around 400 miles, giving the new Mirai genuine long-distance driving capability.

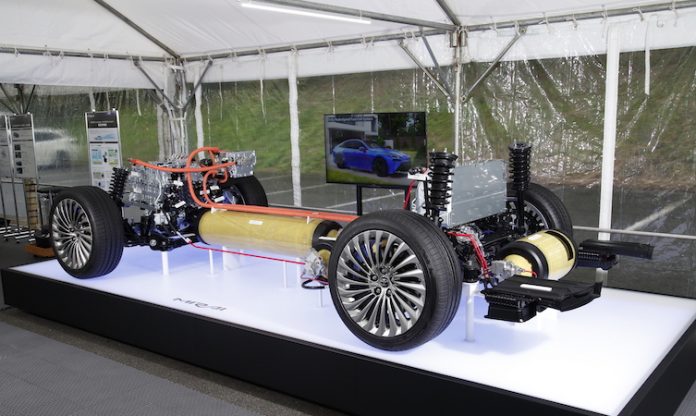

The new Mirai’s packaging has also been significantly improved, largely thanks to the use of Toyota’s modular GA-L platform. A redesigned and more efficient FCEV powertrain, notably with the fuel cell stack moved from beneath the cabin to the front compartment (equivalent to the engine bay in a conventional car), has allowed for a more spacious, five-seat interior with improved legroom for rear-seat passengers.

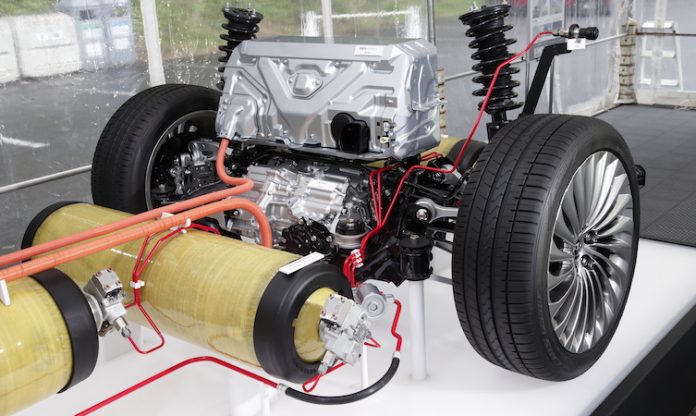

Crucially, the adoption of the new GA-L platform has enabled the fitment of a third high-pressure hydrogen fuel tank. The new tanks have a stronger, multi-layer construction and are arranged in a ‘T’-configuration, the longest running longitudinally and centrally beneath the vehicle floor, with two smaller tanks set laterally beneath the rear seats and luggage compartment. Together they can hold 5.6kg of hydrogen, compared with 4.6kg in the current Mirai’s two tanks.

Additionally, the high-voltage battery and electric drive motor are positioned above the rear axle. This optimised powertrain and fuel tank layout helps contribute to the new Mirai’s ideal 50/50 front-to-rear weight distribution.

Mirai hydrogen fuel cell: emotional appeal

One of the principal aims for the new Mirai has been to give the car a stronger emotional appeal, making it attractive as much for its looks as it is for its environmentally-friendly performance and the way it drives. The new GA-L platform and Toyota’s advances in FCEV technologies have together made this possible.

The new Mirai benefits from more attractive proportions. Overall height has been reduced by 65 mm to 1,470 mm, and there is a 140 mm increase in the wheelbase, to 2,920 mm. With the rear overhang extended by 85 mm, overall vehicle length is now 4,975 mm. A 75 mm increase in the track width and the use of larger, 19-inch front and 20-inch rear wheels give a more dynamic stance and offer a visual representation of the new Mirai’s lower centre of gravity.

Mirai’s hydrogen fuel cell stack

Toyota’s new fuel cell stack and fuel cell power converter (FCPC) have been developed specifically for use with the GA-L platform. All the elements in the stack frame – including the water pumps, intercooler, air conditioning and air compressors, the hydrogen recirculation pump and the stack case itself – have been brought together and made smaller and lighter, while at the same time improving performance. By concentrating the system connections within the case, fewer components are needed, again saving space and weight.

The fuel cell stack uses a solid polymer, as in the current Mirai, but while it has been made smaller and has fewer cells (330 instead of 370), it sets a new record for specific power density, at 5.4 kW/l (excluding end plates). As a result, maximum power has risen from 114kW (153bhp) to 128kW (172bhp). Cold weather performance has also been improved, with start-up now possible at temperatures from as low as -30°.

2021 Toyota Mirai – technical specification

| Power system | 128kW Fuel Cell Stack |

| Power density | 5.4 kW/l |

| Motor | 134 kW electric – rear wheel drive |

| Fuel | 5.6kg compressed hydrogen |

| Range | Approx. 400 miles (approx. 30% greater than current model) |

| Seating capacity | 5 |

This focus on innovation and improvement across every powertrain component has delivered a 50% weight reduction yet a 12% increase in power.

The new unit also incorporates the Fuel Cell DC-DC Converter (FDC) and modular high-voltage parts, while achieving a 21% reduction in size over the current system. Weight has been cut by 2.9kg to 25.5kg. Toyota’s first-time use of a next-generation silicon carbide semiconductor material in the intelligent power model (IPM) transistors has enabled an increase in output and lower power consumption while using fewer transistors, which in turn allows the FCPC to be made smaller.

Elsewhere, the air intake contains sound-absorbing material so noise from the air inlets is unnoticeable in the cabin, while the exhaust has a larger-capacity silencer, which also contributes to the quieter cabin. The complete air system is almost 30% smaller than in the current Mirai and weighs 34.4% less.

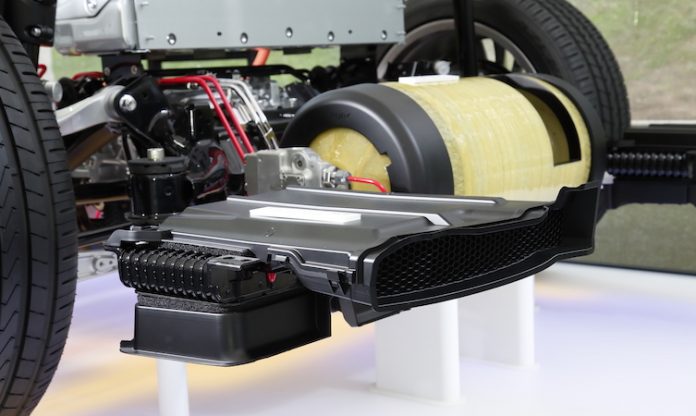

Mirai hydrogen fuel cell: new lithium-ion battery

The new Mirai is equipped with a lithium-ion high-voltage battery in place of the current model’s nickel-metal hydride unit. Although smaller in size, it is more energy-dense, giving a higher output and superior environmental performance. It contains 84 cells and has a 4.0 Ah capacity versus 6.5 Ah of the current Mirai. Weight has been reduced from 46.9 to 44.6kg and output has improved from 25.5kW x 10 seconds to 31.5kW x 10 seconds.

The battery’s air-cooling path has also been optimised, with discreet inlets either side of the rear seats.

Mirai hydrogen fuel cell: an engaging drive

The adoption of the GA-L platform has given the new Mirai a lower centre of gravity, which helps to deliver superior dynamic performance and the fundamental stability characteristics of a front-engined car. The improved dynamics are also aided by increased body rigidity, which has been achieved with strategic bracing and the wider application of adhesives.

The new platform adopts new multi-link front and rear suspension in place of a front MacPherson strut and rear torsion beam arrangement. Thicker anti-roll bars are also used, along with optimised upper and lower ball joint location and overall improved suspension rigidity. This new set-up provides high levels of stability, responsiveness and ride comfort.

Further benefits are gained with the use of larger wheels and tyres. The 19-inch front and 20-inch rear wheels are fitted with 235/55 R19 and 245/45 R20 tyres respectively, with low rolling resistance and quiet running contributing to fuel efficiency, stability and quiet cabin environment.

The Mirai’s improved aerodynamics and lower drag coefficient figure, aided by a lower roof line and full underbody cover, contribute towards the improved dynamics and the increased cruising range.

The new Mirai also rewards its driver with an improved driving character. The extra power of the new fuel cell stack and battery is harnessed for smooth, linear takeoff, while highway driving is relaxed and stress-free, with excellent throttle response at all speeds. When driving on winding roads, the Mirai’s dynamic poise is complemented by strong acceleration out of bends.

Innovative filter

A catalyst-type filter – a Toyota innovation – is fitted in the Mirai’s air intake. As air is drawn into the vehicle to supply the fuel cell, an electric charge on the filter’s fabric element captures microscopic particles, including sulphur dioxide (SO2), nitrous oxides (NOx) and PM 2.5 particulates. The system removes 90-100% of particles between 0 and 2.5 microns in diameter from the air as it passes into the fuel cell system.

Targeting a 10-fold increase in sales

With the introduction of the second-generation Mirai, Toyota is targeting deeper market penetration with a 10-fold expansion in global sales volume. This growth will be supported by the new model’s stronger performance and greater customer appeal, notably as a more affordable vehicle with a selling price reduced by around 20%.

The practicality of hydrogen FCEV ownership will also steadily increase as markets improve their hydrogen infrastructure, the number of filling stations rises and governments and local authorities introduce new incentives and regulations for cleaner mobility.

Read more How the Mirai fits into the wider hydrogen society

Read more Toyota Mirai helps ZeroAvia fly high on hydrogen

I like the new Toyota Mirai, but in the UK we don’t have a refuelling infrastructure. Please take a minute to sign and share my petition for a refuelling network on public forecourts. https://petition.parliament.uk/petitions/561614

Why should the UK government be using taxpayers money to pay for hydrogen refuelling infrastructure when only a tiny number of hydrogen cars are here? If this is such a good idea why isn’t Toyota investing money in its own refuelling network in exactly the same way Tesla has done globally?

The UK government should “invest” in H2 filling stations because it would allow clean, long distance personal and public transport and freight haulage with zero emissions. these currently produce much of our air pollutants. It would allow quick refueling for commercial transport and bus/coach systems that have to maintain a strict schedule.

Another consideration is that in providing charging stations, Tesla has increased the cost of its cars. Its a sad fact that if all current fossil fueled vehicles were to convert to battery power overnight, our power infrastructure wouldnt handle it and therefore the tax payer ( as in buyer of electricity) would end up paying anayway just to keep the house lights on at night. Therefore, it does make sense for the government to sponsor the introduction of a hydrogen infrastructure which is, lets face it, potentially less reliant on nuclear power.

The care looks amazing & the most important thing I loved is it is electric one as I love the nature & I don’t want anything which hampers our environment.

Sorry, but the Mirai simply can’t compete with BEVs

The process of producing hydrogen by electrolysing water and compressing it to the pressure needed to to transfer the hydrogen to the tanks on the Mirai requires approx 59Kwh of electrical energy for every 1Kg of hydrogen produced.

According to you figures, the Mirai can travel approx 400 miles on the 5.6Kg of hydrogen it can carry.

That 5.6Kg of hydrogen required 330Kwh of energy to produce it (5.6*59)

Travelling 400 miles on 330Kwh of energy means that the Mirai travels 1.212 miles per Kwh

That’s the same as saying the Mirai uses 825wh of energy per mile

This table lists the energy use per mile of most BEVs available at the moment

https://ev-database.uk/cheatsheet/energy-consumption-electric-car

Note that the average energy usage is 306wh per mile, the best is 243wh per mile and the worst is 450

The 825wh per mile for the Mirai does not compare well with any BEVs currently available in the UK and is 270% worse than even the average BEV

I would like to mention that by energy density FCEV is far ahead as 1kg of hydrogen contains 33.33kWh of usable energy for BEV battery it will be just 200-300Wh/kg. Sorry, but for vehicles the power, weight and charging times surely have to be considered as well.

FCEV definitely has a number advantages over BEV for certain vehicle types / markets and long term it is the only feasible solution.

FCEVs have a number of advantages over EVs I agree but it’s a bit disingenuous comparing energy density per mass of batteries/packs vs the hydrogen element alone . To produce the electrical current (and recover energy) as a battery pack does but from the hydrogen you need the tanks to store it (that are neither lightweight or small in volume) ,the fuel cell, the fuel cell DC-DC converter ,the necessary air filtration and treatment system, and the traction/buffer battery (I deliberately left some bits and bobs ).

Arman – if you are talking about energy density by weight, you can’t sensibly talk about the hydrogen itself – not unless you’ve developed a pressure tank which weighs nothing! 700 bar tanks weigh about 20x the mass of hydrogen they contain, and that’s what is important. In terms of weight you also need to think about that of the fuel cell itself, and all the other things not needed in a BEV.