In 2016 Toyota became the first car manufacturer to use a new biosynthetic rubber product in its engine and drive system hoses.

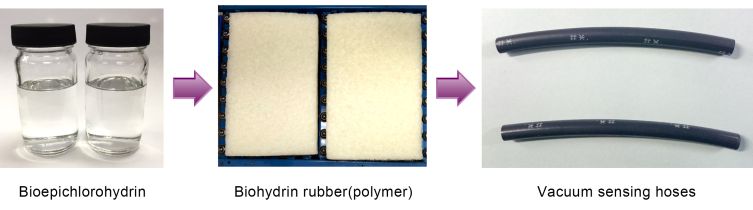

The new biohydrin rubber is made using plant-derived bio-materials instead of the epoxy compounds commonly used in conventional hydrin rubber. Since plants naturally absorb CO2 from the atmosphere while growing, it has been estimated that this newly developed bio-material will reduce lifecycle carbon emissions by around 20 per cent compared to conventional petroleum-based hydrin rubber.

The first vehicles to use intake hoses made from biohydrin rubber were produced in May 2016, with applications expected to be rolled out to all Toyota automobiles manufactured in Japan by the end of the year. In the future, Toyota plans to expand the use of biohydrin to other high-performance rubber components such as brake and fuel line hoses.

Production of biohydrin rubber requires a variety of compound technologies in order to bond plant- and petroleum-derived materials at a molecular level. These technologies ensure that biohydrin provides the levels of oil resistance, heat resistance and durability required for hoses in engines and drive systems.

Using biohydrin rubber in vehicles represents a small but important step toward meeting a range of ambitious environmental targets collectively referred to as the Toyota Environmental Challenge 2050. These targets represent the company’s comprehensive map for contributing to global environmental sustainability.

Toyota will continue to develop and commercialise technologies that enable the use of materials like ecologic plastics and biosynthetic rubber in a wider range of components.

Read more: Toyota staff capture biodiversity at Eco HQ

Read more: What is the Prius Biometric Drive?

Details in this article were correct at the time of publication.