Toyota has set itself six environmental challenges that it plans to have in effect by 2050. As well as achieving zero environmental impact in all vehicle-related activities, Toyota wants these initiatives to have a positive and sustainable impact on society as a whole.

The six environmental challenges are listed below, followed by a detailed description of how Toyota plans to implement the third challenge by 2050. Click on any of the further links to be taken to separate posts describing how each challenge will be implemented.

Toyota Environmental Challenge 2050:

1) Zero CO2 emissions in new vehicles

2) Zero CO2 emissions throughout a vehicle’s life cycle

3) Zero CO2 emissions from all production facilities

4) Minimising and optimising water usage

5) Establishing a recycling-based society and systems

6) Establishing a future society in harmony with nature

Challenge 3: zero CO2 emissions from all production facilities

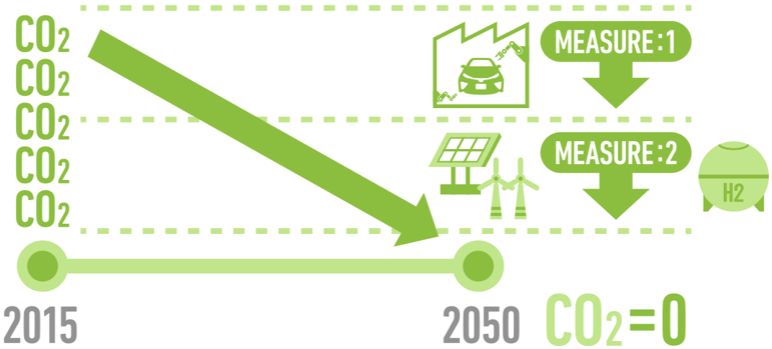

Toyota has challenged itself to reduce to zero all CO2 emissions produced by its production facilities. It aims to achieve this by developing and introducing low-CO2 technologies, as well as adopting renewable energy sources and utilising hydrogen energy.

Why is it needed?

Not only do most vehicles emit CO2 while driving, CO2 is generated during the manufacturing process. Therefore the challenge to tackle climate change must also be directed at the production facilities that manufacture our vehicles.

What is Toyota already doing about this challenge?

Toyota’s strategy to achieve zero CO2 emissions at its production facilities involves improving manufacturing technology and switching to different forms of energy. These eco activities are being implemented at Toyota factories throughout the world.

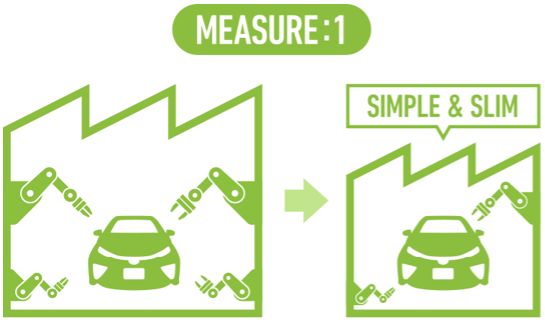

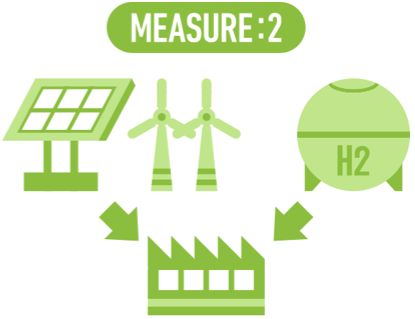

With regards to manufacturing, processes are being simplified and rationalised in order to shorten them and reduce time, thereby cutting CO2 emissions. Improved efficiency in energy use is also reducing emissions. For instance, processes that do not use energy are being introduced where possible, and we are adopting new energy sources such as solar, wind and hydrogen fuel cells.

Toyota has been measuring and setting emissions targets for production facilities and offices for many years. For example, during 2015 the combined CO2 emissions of all Toyota premises in Japan was calculated to be 1.15 million tonnes, a figure that is 45% lower than that calculated in 1990. From a worldwide perspective, the volume of CO2 emitted per unit has also steadily decreased over the years. During the production of each vehicle, today’s models release 36.6% fewer CO2 emissions into the atmosphere compared to that calculated in 2001.

Did you know? The Toyota Motor Manufacturing UK factory in Burnaston, Derbyshire, was the first facility of its kind to achieve ISO 14001 environmental certification and is one of the only sites to send zero waste to landfill.

Learn more: Solar energy helps power Toyota’s Burnaston factory

Learn more: Toyota’s Honsha Plant adopts hydrogen fuel cell power