Toyota has set itself six environmental challenges that it plans to have in effect by 2050. As well as achieving zero environmental impact in all vehicle-related activities, Toyota wants these initiatives to have a positive and sustainable impact on society as a whole.

The six environmental challenges are listed below, followed by a detailed description of how Toyota plans to implement the fourth challenge by 2050. Click on any of the further links to be taken to separate posts describing how each challenge will be implemented.

Toyota Environmental Challenge 2050:

1) Zero CO2 emissions in new vehicles

2) Zero CO2 emissions throughout a vehicle’s life cycle

3) Zero CO2 emissions from all production facilities

4) Minimising and optimising water usage

5) Establishing a recycling-based society and systems

6) Establishing a future society in harmony with nature

Challenge 4: minimising and optimising water usage

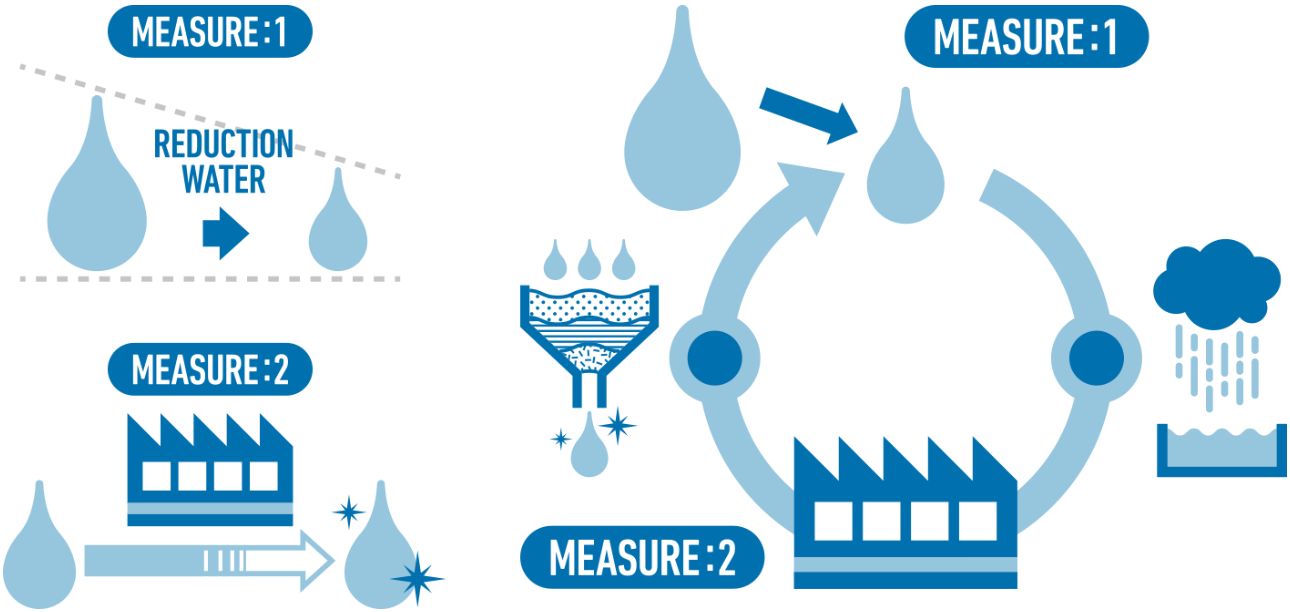

Toyota has challenged itself to minimise and optimise water usage throughout the manufacturing process. It aims to achieve this by comprehensively reducing the amount of water used and by purifying the water that is consumed so it can be returned to the earth.

Why is it needed?

It is estimated that the world’s population will rise to 9.1 billion by 2050, increasing demand for water by 55% over current levels. As a result, 40% of the world’s population will likely suffer water shortages.

In automobile manufacturing, water is used in painting, forging and other processes. Therefore, even a small reduction of its impact on the water environment is important.

What is Toyota already doing about this challenge?

Although local water environments differ greatly according to region, Toyota intends to roll out a range of measures globally to deal with water in a way that is sensitive to local needs. So far, Toyota has implemented a number of water-saving measures. These include rainwater collection to reduce the amount of water used by production plants, filtering to increase the water recycling rate, and re-use of wastewater through recycling.

On a global level, this has resulted in a reduction of water usage per vehicle from 4.8 cubic metres in 2001 to just 2.7 cubic metres in 2015. Included within these figures is the efforts of Toyota’s UK manufacturing site at Burnaston, which processes more than 250,000 cubic metres of waste water a year. Metals and other contaminating materials are filtered out so that the water is clean enough to enter the sewer system, while the material left behind is recycled for the construction industry.

Learn more: Toyota recycling helps build the future

Learn more: Which Toyota model emits nothing but water in use?