Toyota’s “lean” manufacturing system needs little introduction. The legendary Toyota Production System has helped shaped business practise since it was established in 1948.

Originally called “just-in-time production,” it builds on the approach created by the founder of Toyota, Sakichi Toyoda, his son Kiichiro Toyoda, and the engineer Taiichi Ohno. The principles underlying the TPS are studied and copied the world over.

But while the Toyota Production System pioneered modern manufacturing as we know it, Toyota New Global Architecture (TNGA) – announced as a development of the Toyota Production System – aims to revolutionise the development of Toyota vehicles by placing more emphasis on harmonising planning and design to increase efficiency.

In simple terms, a greater focus on standardised parts and components means Toyota’s future cars will be better to look at and more engaging to drive. They will also be easier to develop, and delivered more quickly and efficiently to customers. In this blog post, we explain why…

Back to basics

The introduction of the TNGA will also increase the efficiency of the development process while reducing costs, which will free up more resources to be used on developing technology, sales, procurement and production techniques.

But the origins of TNGA were rooted in recent history. According to Mitsuhisa Kato, one of Toyota’s Executive Vice Presidents, the inspiration for the revolutionary TNGA came just after the collapse of Lehman’s bank in 2008, an event that led to the global ‘credit crunch’ and a widespread economic slowdown.

‘It was’, Kato-san said, ‘a fresh reminder that Toyota needed to be able to achieve sustainable growth. The whole company had to change direction.’

What was done?

At the launch of the TNGA project at Toyota’s HQ, Kato-san added that Toyota’s system of appointing an effectively independent chief engineer to each new model project had led to a proliferation of models, platforms and engine derivatives.

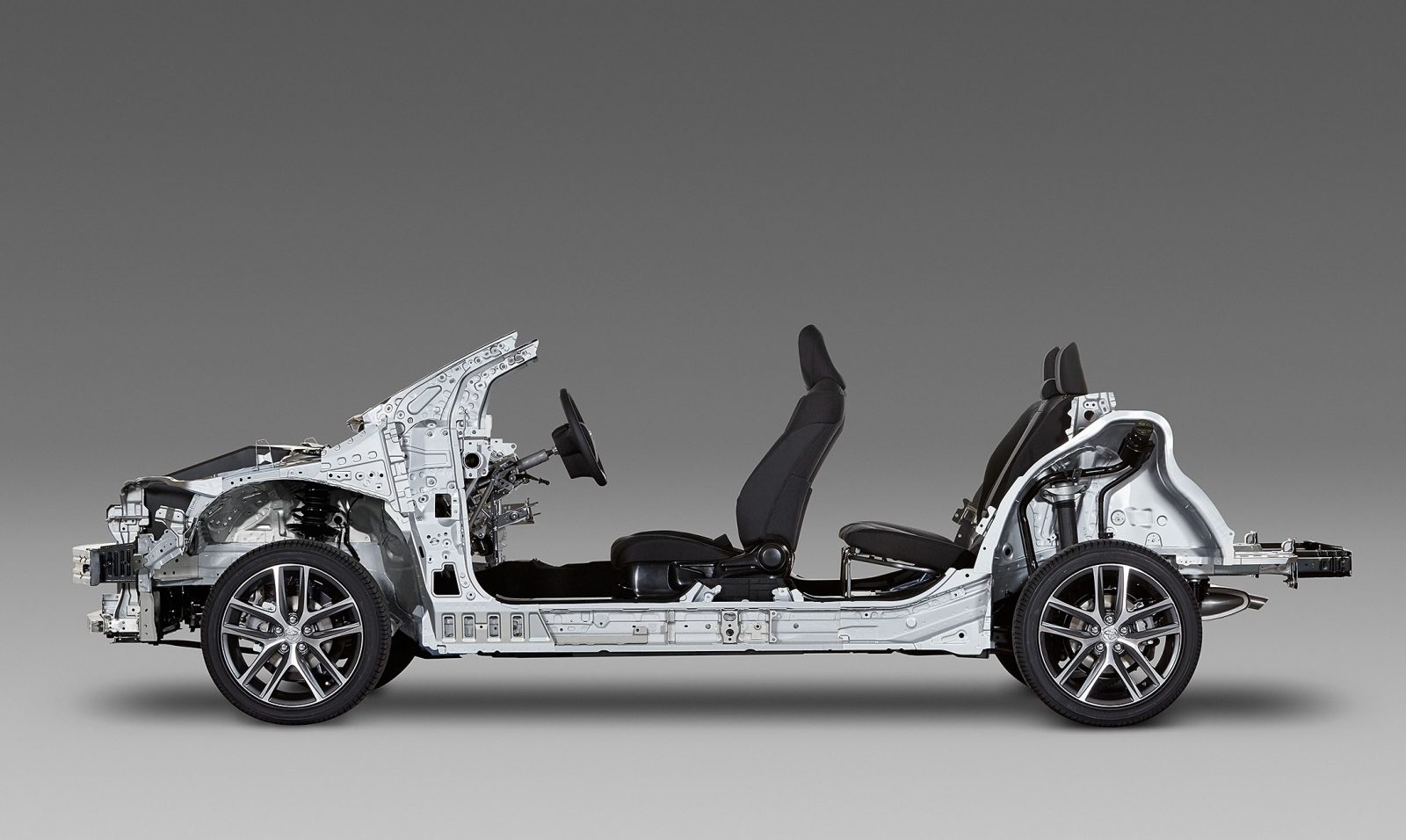

Ironically, Toyota’s admirable intention of building cars to meet local demands around the world had resulted in as many as ‘100 platforms and sub-platforms’ in the automaker’s product line up. A platform is the sub-structure of a car, around which a vehicle is designed, engineered and constructed.

Also, the number of powertrains, including engines modified to fit all these different platforms, numbered as many as 800. Such a wide range of components and models also makes it ‘hard to improve on individual models [during their production life time]’.

But Toyota management didn’t just stop at having to completely re-think and re-engineer the platforms and powertrains that would underpin its future models (a process that took place between 2009 and 2011). According to Kato-san, it also decided that it needed to ‘improve the basic performance of its cars’ but also to ‘build attractive and eye-catching cars’ for the future.

Toyota’s engineers were also asked to ‘drive as much as possible, especially outside working hours: love cars.’

It was a brave admission, but Toyota has long been the master of production engineering. In an increasingly competitive future, the company would need to balance the rational engineering with passion for the end product. To this end, Toyota’s production engineers were encouraged to dream up ‘ever-better’ vehicles, being asked by the company to ‘experiment, think and feel…get our hands dirty’ according to the internal briefing.

As well as proposing projects on paper, Toyota’s engineers were also asked to ‘drive as much as possible, especially outside working hours: love cars.’ Toyota’s engineering chiefs also vowed to learn from the automotive opposition, benchmarking rival vehicles and ‘studying technologies from around the world’. One of the results, say company engineers, is that TNGA models will have much improved driving dynamics because this platform has one of the lowest centres of gravity amongst its competitors.

See also

TNGA explained: Toyota’s human touch

TNGA explained: 10 ways Toyota is changing how cars are built

The promise is for cars that are better looking, better to drive and better specified.

The first result of all this work is the TNGA platform, which is designed to give the chief engineers of these upcoming Toyota models enough flexibility to build all kinds of these ‘new-era’ vehicles with the minimum number of different components.

To that end, for example, the TNGA kit of parts can have the front seats placed at as many as five different heights – perhaps the crucial engineering distinction between different types of vehicle – allowing cars from low-rise sporty coupes, to high-rise SUVs and crossovers to be built with the same component set.

What does it mean for you?

Perhaps the best news for future Toyota customers is that Kato-san promised that the majority of money saved by using TNGA would be ploughed back into the development of even better cars for the future.

The promise – to be tested from this year with the first TNGA-based production car – is for cars that are better looking, better to drive and better specified. But ‘sustainable growth’ demands no less.

I am studying MBA at University of the People and this article is one of my readings in an Operational Management class. This is a great opportunity to pour my hearts out about what I feel about TOYOTA brands in which I am a loyal customer. I drive a TOYOTA CAMRY 2003 model in Nigeria where TOYOTA commands huge market share due its resilience, durability, fuel/gas efficiency and simplicity to drive. However, despite all these aforementioned qualities, TOYOTA has a very poor external DESIGN and an AWFUL DASHBOARDS compared to its rival, HONDA. For instance, the look and feel of the TOYOTA VENZA brand from 2010 which is a mini SUV, is very poor compared to the 2010 range of HONDA sedan cars in terms of designs and dashboards. The DASHBOARD gives an aesthetic aura to the vehicle but TOYOTA seems, whether deliberately or inefficient, not bothered about this critical part of the car. Hopefully, TNGA will address these issues.

Looking for the point of machanical design, if TNGA is in effect to standardize the platform and subplatform, it means there’s less room for user-interface complex. The external and internal design conflict and TNGA seems to drive down systemic costs by reducing internal options. I imagine that TNGA will result in much more price competitiveness rather than how it looks.

Besides, the cost factor, humans like differentiation rather than uniformity -which is why there are different automakers in the first instance. Qualitywise, Toyota dashboards are among the lowest in quality I have seen: a lot of 2007-2012 Camry cars in my city have covers placed over their dashboard because the material melts under the sun, making it sticky to the touch! A 1998 Volvo S70 has folding mirrors which a 2007 Camry doesn’t. Toyota designs are beautiful, but they need to bring quality of materials to the fore to attract some customers who are turned off by their cheap details. I wish Toyota good luck with TNGA.

I think that Toyota has relatively good external design, but many of its features are very standardized in my point of view. I think that the point of TNGA is due to it being practical but also cost-effective for manufacturing, so they can keep offering low, competitive prices for their vehicles.

Hi Mohammed,

Thank you for the comment, this has been my critic on TOYOTA vehicles, my major complaints are the external design and the interior from the dashboard to the entire fabric’s interior.

Hi Uche,

Thanks for your feedback.

We appreciate that design is subjective and that not everybody can like the same things.

What would you like to see in a new Toyota vehicle?

Thanks.

Brand loyalty is not what it once was. Though I do appreciate the lean manufacturing that Toyota has built, and their desire to use minimal parts for a wider variety of cars, my loyalty is to the cost these days. I make good money and am what I would consider not rich, but richer than middle class. That being said, in no world or universe am I every going to pay more than ~35k for a vehicle. These car companies are selling way too many vehicles with hefty price tags.

I’d like to see a car company do what Toyota is doing with TNGA, but make AFFORDABLE cars! We forget that cars are a means of transportation. I refuse to be car poor. So Toyota…keep refining the TNGA and revolutionize the industry by passing the savings of efficiency into the price tag. It would be cool as hell if a car company could release a vehicle that is more than a step above a Fred Flintstone experience, and for less than $10,000! That’s the adventure, that’s the challenge!

Hi there,

Thanks for your comment.

We appreciate your interest in our manufacturing processes. We are constantly innovating our products, so who knows what we could release in the future?

Thanks.

The best car you could work on and release in the near future is one that is stunning in appearance and functionality but only costs $10,000 or less. China is already doing this, with brand new cars costing $5,000 or more. Why isn’t Toyota getting on board?

I am student at University of the People studying my MBA. I have been driving Toyota Corolla 2008 model since 2013 till date. TNGA should address the dashboard and make the seats more comfortable for all Toyota models

I want to say that not all Toyota cars have same dashboard, I’ve been lucky to drive different variants of Toyota and so I think Toyota company is so immersed in class, I say this because the land cruiser has superb exterior and interior designs. I believe Toyota Rav 4 has a fair interior and as well as the premio. I do hope that rather than import Toyota cars to Africa, Toyota should have a branch in the eastern part of Africa precisely kenya where I know the vehicle ahead of you is always a Toyota.

Dear viewer

I went thro all the review and articles and views about everyone according to prosperity .

I am also MBA students of university of the people.

Toyota car is made up super immense property and good durability .

I still see a lot of government of nepal office very old Toyota car running on road .

Although people use honda as choice as well.

In Haiti, TOYOTA cars are very much in demand, old or new. When we say TOYOTA we mean durability, efficiency and good price. Everyone wants or wishes to have a TOYOTA

In Cameroon, almost every car owner drives a Toyota. New models like Vitz, Blade, Auris, well I call them new because that’s what we are experiencing here. They look great and are cheap I suppose because almost everyone is driving a Vitz.

Hi all, I think we are all saying the same thing here. Quality plus low price. This is what everyone wants and this is what I think Toyota is up to. However, the outlook can have a touch of the new industrial revolution.