Have you seen our new collection of Le Mans heritage GT86s? As you can imagine, they cause quite a stir on the road and prompt dozens of questions. To help address these, this post reveals how the cars were modified and identifies the aftermarket components used in their construction.

Every element of each racecar’s livery was replicated and adapted to suit the GT86. This is the GT86 x TS050 being readied for application

Each of the three Toyota GT86 models feature a visually arresting livery created and applied by the vinyl graphic specialists at Funkee Fish. All of the vinyl graphics were laid over factory body colours: Pearl White for the TS010 and TS050, and Pure Red for the TS020. Careful reference was made to archive material to ensure that all the shapes, colours and logos of the original race liveries were replicated as closely as possible around the sleek but very different shape of the GT86.

Under the altered visuals, we decided the GT86s should share the same aftermarket suspension, wheel specifications and exhaust components – most of which had been used to great effect in a previous retro livery series. With regards to the exhaust, we wanted the cars to sound as evocative as they looked. So we got in touch with exhaust manufacturer Milltek Sport to supply us with fruity cat-back systems to replace the standard pipework.

Milltek Sport exhaust system is secured in place using the original mounting points

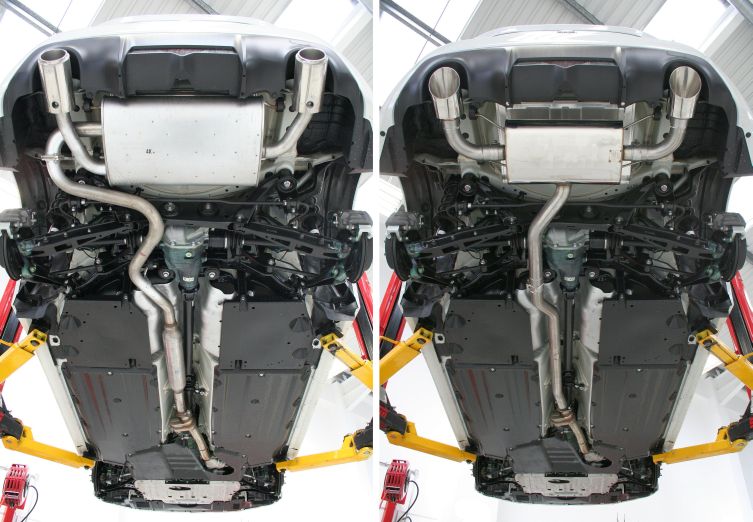

Beautifully constructed in mandrel-bent stainless steel, the Milltek Sport system deletes the primary in-line silencer that nestles within the transmission tunnel and further optimises flow by directing the pipework into the centre of the main silencer rather than around into the side (see comparison images below). In so doing this opens the possibility of simplifying the overall appearance of the system and improving the way exhaust gas is ushered towards each tailpipe. This is achieved by hiding a perforated Y-shaped separator inside the main silencer so that exhaust noise is dampened without the gases losing momentum or direction.

Compare the routing and design between the standard GT86 exhaust system (left) and the free-flowing Milltek Sport cat-back system (right)

Fitment was straightforward thanks to Milltek Sport adopting all the standard location points and rubber hangers. Plenty of adjustment was also available within the exit branches, which proved useful when fine-tuning the position of the tailpipes within the cut-outs of the rear bumper.

A lower ride height was essential in adding a dramatic racecar appearance and to properly frame the aggressive new wheel designs we have fitted. But as these are road cars, there was no need to fit race-inspired, height-adjustable coilover suspension units. Instead, we chose to install progressive rate V-Maxx lowering springs designed to work alongside the original dampers. Two versions are available for the GT86, offering either a 30 or 40mm suspension drop on both axles. We chose the lower option.

Our V-Maxx lowering springs feature progressive rate coils to provide a balance between comfort when cruising and rigidity when cornering.

Supplied by The Performance Company, V-Maxx Sportsprings have a solid reputation within the tuning community, founded on TüV-approved construction and spring rates that strike a favourable balance between sporty handling and ride comfort.

Spring clamps are needed to keep the coils under compression during reassembly

Installation of the springs required the removal and disassembly of the original struts. Caution has to be exercised when taking the struts apart as the coils are held under compression and will violently launch free if not held tight in a special spring vice. The same care needs to be taken as the struts are reassembled. Once again, fitment was superb, with the coil ends lining up perfectly with the hollows formed into the original spring cup seats.

Just as the vinyl graphics set each car apart, the same is true of the new alloy wheels. Our aim was to faithfully replicate the wheels of each racecar by choosing from designs produced by aftermarket suppliers, though in the case of the TS050 this turned out to be the most tricky element of the whole project.

Wheel designs from left to right: Rota MXR, Rota Roku and custom Image Billet 60

Our first call was to Rare Rims, a supplier that divides its alloy wheel range between retro-inspired and motorsport designs. We challenged the team to see if it could source wheels that closely matched those seen in the archive images we supplied. Not only that, they had to match a specification that is more aggressive in appearance but still works well on a lowered GT86: 8.5-inch width, 18-inch diameter, and a hub offset of ET45.

Two of the designs they came back with were incredibly close in appearance to the wheels originally fitted to the TS010 and TS020. The former was the Rota MXR, a gold wheel with V-shaped spokes and contrasting silver rim, while the latter was the all-black Rota Roku, another motorsport-inspired design but with six sets of parallel spokes.

Finding a wheel with a similar design to the Rays-made, centre-locking magnesium alloy wheel of the TS050 Hybrid was tricky

Despite searching high and low, no off-the-shelf aftermarket wheel could get close to the design of the Rays-made, centre-locking magnesium alloy wheel of the TS050 Hybrid racecar (above). Our next option, therefore, was to approach bespoke manufacturer Image Wheels for a custom creation. A broad variety of options within Image’s three-piece alloy wheel range led us to the flat-face appearance of the popular Billet 60 wheel centre – a directional design with gently angled cooling apertures around the circumference.

Knowing what sort of look we wanted to achieve, production manager Jason Worrall talked us through the configuration possibilities of the three-piece construction. He recommended reducing the depth of the outer rim to increase the impression of a flat face design. He also specified hidden assembly bolts, a billet centre plate with a screw-on nut to mimic the TS050’s centre-lock mounting system, and an all-over anthracite grey paint job. After patiently waiting a couple of weeks for our turn on the production schedule, the custom-made wheels arrived. And we think they look smashing.

With new suspension and wheels now installed, the only thing remaining was to restore the geometry to within factory tolerances for straight-line stability and even tyre wear. After this was complete, the cars were ready for their group video shoot at Toyota Motorsport GmbH in Cologne, Germany, alongside their racecar equivalents.

Next week we will examine the individual histories of each of the endurance racers that inspired our Le Mans heritage GT86 models.