Until the late 20th Century, most production vehicles fitted with a spark ignition internal combustion engine adopted a traditional Otto-type four-stroke piston cycle.

As the name suggests, these four-stroke engines have four separate phases within a single cycle – intake, compression, combustion and exhaust – and each phase corresponds to a full piston stroke inside the cylinder.

The cycle begins with a downward piston stroke, which draws a mixture of air and vapourised fuel through the intake valve opening into the combustion chamber. The upward stroke of the returning piston compresses this mixture to around one-tenth of its volume, at which point it is ignited by the spark plug. This explosion drives the piston downward in a stroke that gives the engine its thrust. The final return stroke of the cycle evacuates the spent gases via the exhaust valve so that the process can begin again.

This relatively straightforward thermodynamic cycle has equal compression and expansion ratios in each cylinder. But while it produces a satisfactory output from any given displacement, the Otto cycle is not the most fuel-efficient way of generating power.

In 1882, a British engineer named James Atkinson developed and patented a modified four-stroke cycle that used a variable length piston stroke and delayed intake valve closing to increase efficiency.

Though effective and incredibly clever, this design didn’t stack up financially for mass production. Complex mechanical linkages were needed to achieve different stroke lengths from a single revolution of the crankshaft, while the benefits in efficiency could only be achieved at the cost of some power. Because of these issues, Atkinson’s ingenious design was largely forgotten about for the best part of 100 years.

However, with the introduction of variable valve timing technology, Toyota engineers realised that they could generate the most vital, fuel-saving quality of the Atkinson cycle – the delayed closing of the intake valve during the compression stroke – through non-mechanical means; hydraulic actuation of the camshaft position.

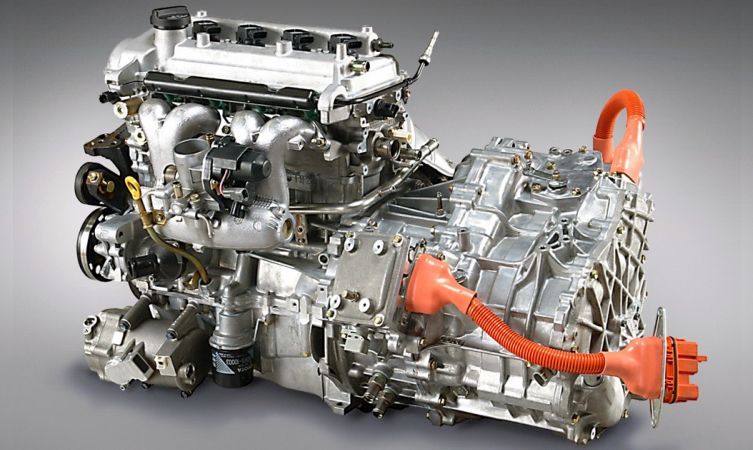

This revelation allowed Toyota to build the world’s first Otto cycle engine with a simulated Atkinson-type valve action to significantly improve fuel efficiency. Known internally as the 1NR-FXE, the 1.5-litre four-cylinder petrol engine was installed in the 1997 Toyota Prius and paired with the fantastic new Toyota Hybrid System (now known as Hybrid Synergy Drive).

Using an electric motor to assist the petrol engine addressed the shortfall of power characteristic of the Atkinson cycle, but also provided an independent source of motivation in order that the engine could be shut off when possible. After all, the most effective method of fuel-saving is not to have the engine running in the first place!

So successful has this pairing of a simulated Atkinson cycle engine with a hybrid electric powertrain that every Toyota and Lexus petrol-electric hybrid model produced since the first-generation Prius has employed the same fuel-efficient architecture.

Why are some Corollas badged ‘HEV’ and others ‘Hybrid’ ?

Hi there,

The “HEV” is on our newest vehicles.

Are you currently considering a Corolla for yourself?

Thanks.

I’ve got one thanks, replaced my Avensis.

Great information about the Atkinson cycle, thank you. It’s a long way from the single-cylinder 2-stroke diesel marine engine that I leaned to love 50 years ago but the simple and brilliant ingenuity of concept is all there, just the same 🙂

I’m in the USA and just purchased a 2025 HEV Highlander. I really like the way the gas engine and the electric motors work together. One think I was wondering about, when I start up it only using the electric motors. Then, at around 20 mph, the gas engine engages. To start gas engine, does it use a conventional starter? Or, since the car is already moving, does the engine get “push started” without the need for an dedicated electrical starter motor?

BTW, I think overall it’s the best car I’ve ever owned since I started driving in ’68.

Hi Frank,

Thank you very much for your question.

We greatly appreciate your enthusiasm in our cars, and congratulations on purchasing your new 2025 HEV Highlander! It’s always encouraging to hear from another satisfied customer.

For further information around our Toyota Hybrids, please follow this link: https://www.toyota.co.uk/hybrid

Alternatively, you can find out more technical information from your Owner’s Manual. Please input your VIN via this link to access your specific vehicle manual: https://www.toyota.co.uk/customer/manuals

If you have any further questions, please do not hesitate to ask.

Many thanks and congratulations,

Toyota UK

AFAIK, the whole thing is quite clever, using Toyota’s mechanical “power split device”, which is basically a planetary gearing system, with its three shafts (ring, planetary, sun). The ICE engine crankshaft is fixed to the planetary, car wheels and electric motor/generator #2 to the ring, and the electric motor/generator #1 to the sun.

When you drive slowly on electric power, the work is done by motor #2 (ring) , sun shaft is allowed to rotate freely (no load on motor/generator #1), so planetary (the ICE engine) can stay immobile.

To start the ICE engine, an increasing load (now charging the battery) is put on motor/generator #1). At the same time, the system proportionally boosts the electric power to motor #2, to keep its RPM stable.

This results in the ICE engine (planetary shaft) slowly to start turning, the faster the larger charging load is put on motor/generator #1, until the system pretty much shorts out the coils of motor/generator #1, stopping it, and thus stopping the sun shaft. At this point, the RPM of the ICE engine and RPM of the motor #2 are matched, the ICE engine can be fed fuel and lit up, and take over, at the same RPM, the rotation of the now synchronized planetary and ring (wheels) shaft. The electric power to engine #2 can be switched off, the car is now on ICE drive.

The above is similar to “push start”, but the speed of the car is not affected as the still working electric engine #2 compensates (using more electric power) for the load of the ICE engine being revved up. And there is no jerk of the clutch getting engaged as in the push-start, there is no clutch in the system. The planetary gear acts as a variable ratio transmission (that increasing sun shaft breaking action of the engine #1), so spinning up the ICE engine is smooth.

The above explanation is simplified for the purpose of “principle demonstration”, but, I think, shows the main idea.

The Atkinson cycle allows fuel and air mixture back into the intake valves which helps to the clean f pm carbon build up.