Chocolate is a treat that can be tricky to eat when travelling… especially when the weather is hot. But even if things do get sticky on World Chocolate Day (7 July), Toyota’s rigorous test procedures mean that confectionary stains should be easier to clean up.

So whether it’s a chunky choc ice lost under the seat or a melted milk chocolate medley in the centre console, technicians from our materials engineering laboratory have probably already been there and tested it. It’s all part of our ongoing effort to build cars that are reliable, long-lasting, comfortable, safe… and fun to drive.

World Chocolate Day: avoiding a choc-shock

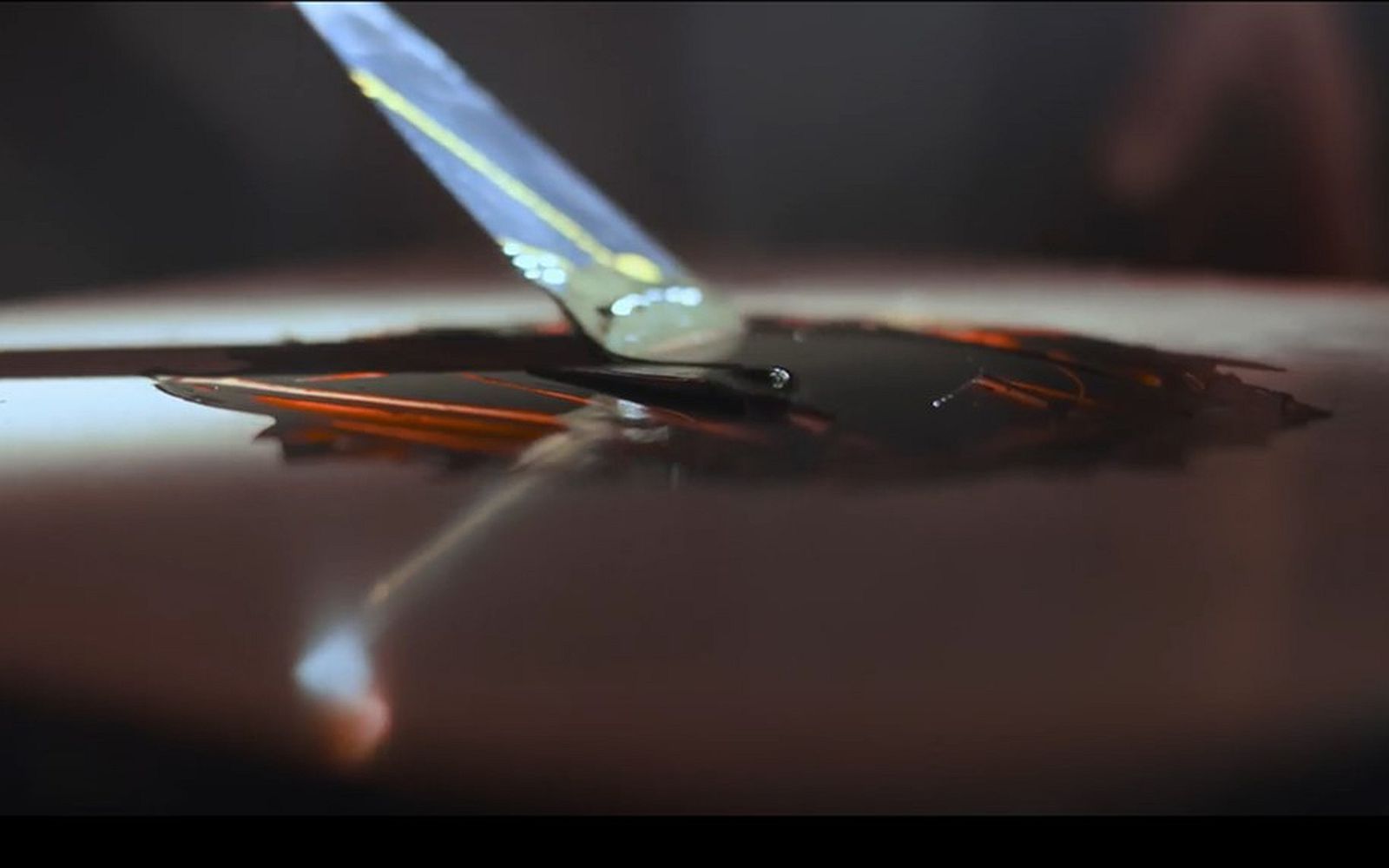

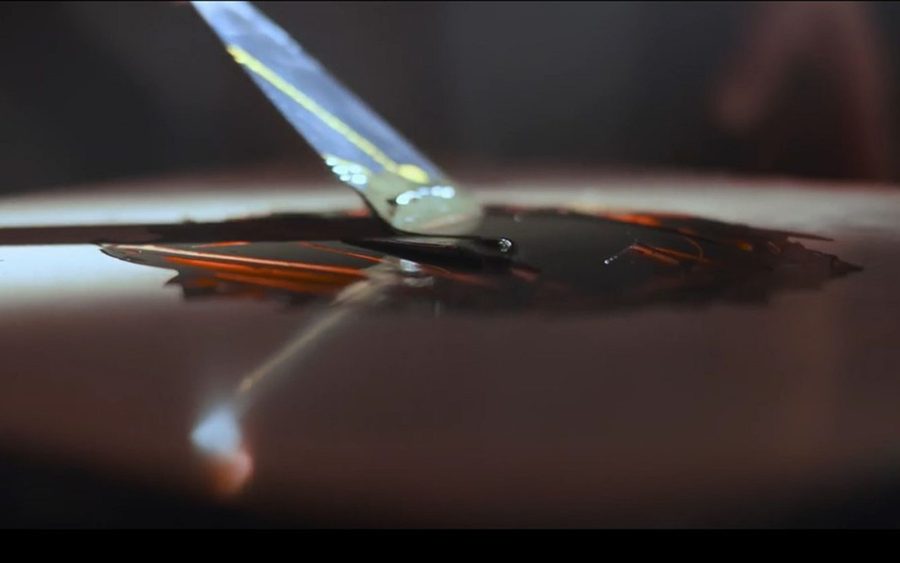

Our chocolate staining test (yes, there really is one) checks how stain-resistant the seat materials are and how easily they can be cleaned if they are marked.

Technicians rub a chocolate bar onto a car seat for different lengths of time, mirroring a common experience for anyone with chocolate-loving children. Next there’s a two-step cleaning process: first, immediate cleaning after staining, then a second test after 24 hours, once the stain has settled in and dried. And to be really thorough, two different cleaning methods are used: one with just water, the other with soap as well.

It isn’t just chocolate that’s given this in-depth scrutiny; the same test is also used for fizzy drinks.

Do Toyota technicians have any other extreme tests?

Absolutely. It is our aim to tackle a variety of everyday issues with the same scientific thoroughness. The following are a couple of additional examples:

Sunscreen test: During the recent heatwave, drivers may have wondered whether oily sunscreen could damage their car’s paintwork. Once again, Toyota has this covered. Sunscreen is applied evenly to a painted test panel, which is then heated in an oven for several hours. After that, the sunscreen is cleaned off and the part checked for any discoloration, shrinkage, blistering or other issues.

Cold impact test: At the other end of the scale, this test assesses the resistance of materials to extreme temperatures. To simulate real-life cold-snaps, car parts – or even an entire vehicle – are deep-frozen to -30°C in a large chamber. Depending on which part is being tested, weights are dropped on to it from different heights and angles (see image above) to test whether it cracks or loses flexibility.

New car scent test: Who doesn’t love the distinctive scent of a brand-new car? Toyota doesn’t design this intentionally; it is a by-product of the manufacturing process. However, in order to make sure that this smell is pleasant, individual parts are put in sealed containers and warmed in an oven (see above). Then, trained smell panellists are invited to sniff the opened containers and judge the pleasantness and intensity of the odour. If the parts don’t match up to requirements, we work with the manufacturers to improve the scent of the materials.

Car washing test: This high-pressure wash test is carried out to confirm how resistant our painted materials are to high-pressure car washing. Depending on which part of the vehicle is tested, water is sprayed at a set pressure and from different distances to check that the paint doesn’t peel off. The closer the spray gun is to the part, the more severe the test.

Read more: Learn about World Chocolate Day