As Toyota Manufacturing UK (TMUK) celebrates its 25th anniversary, we’ve selected 25 objects that represent the most significant processes, equipment and locations that have played a pivotal role in the production of every Toyota vehicle produced in the UK.

Spanning TMUK’s 25-year history, the selection reveals where the company started, how its manufacturing processes have changed over the years, and how TMUK’s facilities continue to lead the way with their technological and environmental innovations.

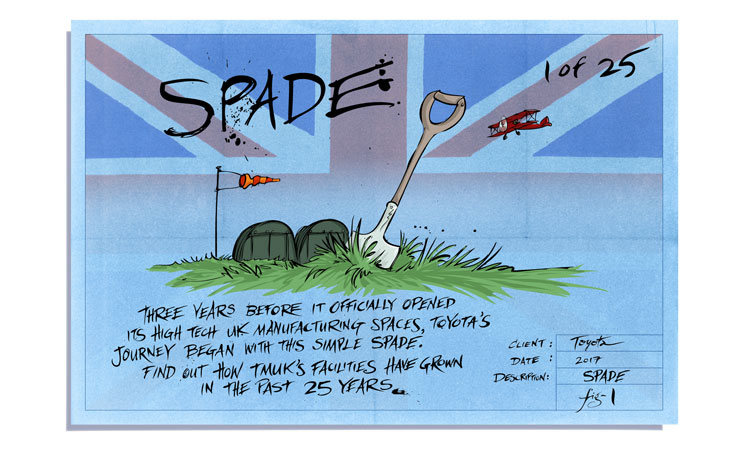

- Spade

Date: June 1990

Two years before it officially opened its high-tech UK manufacturing spaces, TMUK’s journey began with this simple spade. Find out how TMUK’s facilities have grown in the years since.

- Push bike

Date: 1992 – Present

As cars are assembled on the production line, bicycles play an important role in keeping Toyota’s internal parts ordering process running smoothly.

- Giraffe crossing

Date: 1992 – Present

No, it’s not a wildlife alert, but it is one of the clever ways that TMUK maintains safety for people and vehicles inside its busy factories. Find out more about the giraffe crossing.

- Signed body panel

Date: 1992 – Present

Toyota members take personal pride in their work, ‘building in’ quality at every step. Explore how this positive attitude is crucial to building great cars.

- Suction cups

Date: 1992 – Present

Moving thousands of carefully shaped, polished and trimmed body panels across TMUK’s assembly halls is delicate work. Find out how simple suction cups help us do it.

- Onsite nursery

Date: 1992 – Present

TMUK is a family-friendly workplace, helping parents maintain a good work-life balance and helping encourage and maintain a diverse workforce.

- Solar array

Date: June 2011- Present

Discover how Toyota’s UK factories harness renewable solar energy to build your Toyota, generating enough power to build more than 7,000 vehicles and 22,500 engines.

- Furnace

Date: 1992 – Present

Learn how every Toyota engine starts life with a baptism of fire in Deeside’s 750° Centigrade furnace, powered in part by solar energy.

- Wildlife

Date: 1992 – Present

Toyota is committed to working in harmony with nature, and at TMUK this extends to building natural wildlife habitats around its factory.

- Roll of steel

Date: 1992 – Present

It comes in flat, but is soon transformed into the strong core and modern exterior of the Toyota parked in your driveway. Learn how we stamp, shape and mould each roll of sheet steel in a high-pressure environment!

- Microscope

Date: 1992 – Present

Learn how Toyota’s commitment to quality leaves no detail unchecked, even testing on a microscopic level.

- Toyota Delivery forklift

Date: 1992 – Present

As well as making cars, Toyota builds a range of specialised vehicles and trucks for use inside its factories. Find out how each is designed to deliver.

- Engine block

Date: 1992 – Present

Discover how TMUK’s Deeside plant manufactures over 280,000 engines each year, including Toyota’s world-leading petrol-electric hybrids.

- Blue parts boxes

Date: 1992 – Present

How do you keep track of thousands of different components? Carefully, that’s how – discover how TMUK manages this challenging task.

- Paint Shop mister and water trap

Date: 1992 – Present

Learn about the innovative methods used by TMUK to ensure a flawless paint job, every time.

- Burnaston member’s uniform

Date: 1991- Present

Each Toyota facility around the world has a distinctive uniform – uncover the meaning of Burnaston’s three stripes and how they relate to every Toyota that rolls off the line.

- Konnyaku Stone

Date: 2016 – Present

The human touch is still needed in TMUK’s high-tech production process. Find out how people are central to Toyota’s focus on quality.

- Godzilla the Robot

Date: 2004 – Present

Meet TMUK’s biggest robot, one of over 500 busy at work every day in Burnaston’s weld shop.

- Andon cord

Date: 1992 – Present

Find out how a simple cord plays a pivotal role in the Toyota Production System, manufacturing principles that have been fine-tuned over generations and are used in all Toyota facilities globally.

- Parts delivery robot

Date: 1992 – Present

Our engineers designed these robots to get the parts where they need to be, just in time – discover how they get the job done.

- Dojo and training

Date: 1992 – Present

Learn how the principles of the dojo are applied to Toyota’s production methods, equipping TMUK’s members with the fundamental skills for the job.

- Spanner

Date: 1990 – Present

This simple spanner is one of many that helped make the Burnaston factory. It’s a reminder that every successful Toyota is the product of hard work by thousands of people.

- Mirrors on the production line

Date: 1992 – Present

Discover how Toyota’s ‘Kaizen’ principle led to the installation of mirrors on TMUK’s production line.

- Overalls in the freezer

Date: 1992 – Present

Keeping everything clean inside our paint facility is a full time – and highly specialised – job! Even the overalls are frozen to help keep them extra clean – find out why.

- Belgian road

Date: 2007 – Present

Discover how a little piece of Belgium plays a vital role in the production of Toyota vehicles as one of our many quality checks.